With the life expectancy of a large solar power installation being 25-50 years, why should you use hot dip galvanized steel, which will last 75 years or more even driven below ground, for posts? It can be tempting to avoid the initial cost of galvanizing by using bare black steel instead, but that will only cause maintenance costs to go up. Trying to solve this problem by specifying heavier, or higher-grade steel, or even corrosion-resistant alloy posts can wipe out any initial savings.

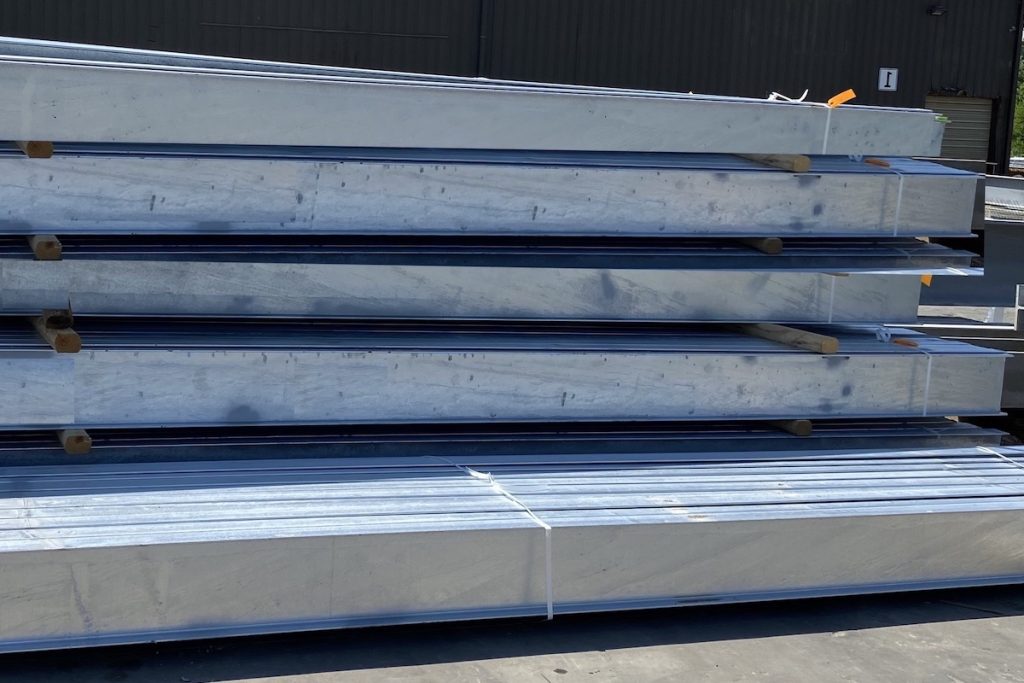

The most specified type of steel used in solar power generation is hot-dip galvanized (HDG) steel. Maintenance-free longevity is a major advantage. Sustainability is another.

Sustainability

Solar energy is naturally sustainable. That’s the point of solar power generation. It converts the sun’s energy into electricity and makes use of the greatest, most sustainable resource on the planet, sunlight. Solar energy technologies and solar power plants do not produce air pollution or greenhouse gases when operating. Environmental friendliness is a driving factor in the growth of solar power.

Using raw black steel posts in solar power generation applications is not sustainable. Their uncertain life expectancy leads to unnecessary replacement, repair and maintenance, which waste resources, energy and money. Eventual removal and disposal of corroded, unusable bare steel posts is an unknown cost that will have to be paid in the future.

Environmental friendliness has always been a feature of hot-dip galvanized steel. Since the raw materials of zinc and steel used in the process are natural elements, galvanizing creates little waste or environmental damage. Zinc and steel both benefit the environment by offering infinite recyclability.

The benefits of HDG steel

Using raw black steel posts in an effort to reduce costs can lead to problems that make the benefits of hot-dip galvanizing even more evident. For example:

- With more than 200 different types of soil identified in North America, the corrosion rate of bare steel in soils is varied and hard to predict. Meanwhile, HDG provides demonstrated longevity to meet typical solar infrastructure design life requirements and additional insurance to ensure a maintenance-free project.

- Bare steel embedded in soils of low corrosivity is not fully protected in instances where solar structures are installed downwind from a chemical plant or exposed to airborne pollutants. Meanwhile, hot-dip galvanizing provides durable corrosion protection above ground, below ground, and in the transition zone.

- Inspection is simplified since the presence of steel corrosion is very easily distinguished from the presence of the galvanized coating.

- HDG provides additional protection against pitting corrosion. The area-averaged corrosion rates of galvanized steel are 3-6 times lower than those of bare steel in the buried environments surveyed, but the pitting corrosion rates of galvanized steel are 4-20 times lower than those of bare steel in the same environment.

- A large percentage of solar utilities are placed in deserts where environmental corrosion is low, but abrasion can be high due to strong winds. Hot-dip galvanizing increases abrasion resistance though increased material thickness and material hardness. Three of the four individual coating layers are harder than the underlying steel making it incredibly difficult to damage even during burial.

- The hot-dip galvanizing finish remains durable through rough handling during shipping, installation, and in-service.

- Hot-dip galvanizing is unaffected by continuous exposure to extreme temperatures ranging from -40 F to 392 F, making it suitable for rugged and isolated climates.

- Solar energy is a field of increasing innovation. When technological advances require installation upgrades, hot-dip galvanized posts will be in good shape to re-use (or in harsher conditions, re-galvanize) for the next generation of solar panels, saving time and money.

HDG steel provides real advantages for the solar industry that far exceed its minimal cost. For lower operational costs, greater profitability and environmental sustainability, always specify hot-dip galvanized solar posts.