1. Does Galvan offer abrasive blast cleaning?

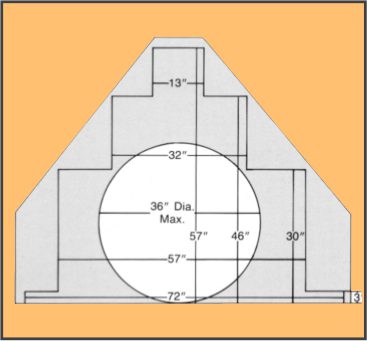

Yes. Our blast cleaning process is computer controlled with automatic loading and unloading. Our blast cleaning cabinet accommodates materials up to 36″ in diameter in any lengths (see diagram on back page). The steel shot used produces a smooth, clean surface ready for finishing. For work pieces too large for the shot blast cabinet, hand sand blasting with abrasive grit is available. All work is processed to SSPC or NACE Specifications. Steel Structures Painting Council Specification, SSPC-10 (near white) is normally produced on the first pass.

2. What blast oil does Galvan use?

MORCOTE 530, a highly-effective, water miscible corrosion inhibitor that offers excellent protection between operations. A data sheet is available on request.

3. What is the largest structure Galvan can dip?

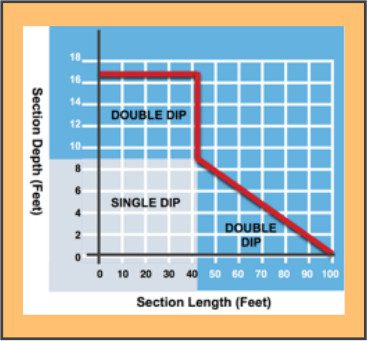

Our hot dip galvanizing kettle is 42′ long x 4’6″ wide x 8’6″ deep. The large bath size, in conjunction with modular design techniques and “progressive” or “double dipping” will allow almost any structure to be galvanized. When a fabrication is too large for single immersion it may be possible to galvanize it by progressive dipping, immersing one end of the work at a time in the galvanizing bath. The capacity chart at right indicates the maximum length of structural sections capable of being galvanized at our facility. The depth of section is indicated along the vertical axis and the corresponding maximum length is shown on the horizontal axis.

4. What is Galvan’s production capacity?

Galvan is one of the largest-capacity hot-dip galvanizers in the Southeast with 59,600 square feet of production space and an annual capacity of 50,000 tons.

5. Does Galvan offer pick-up and delivery service?

Galvan has a fleet of semi and short trucks to provide transportation for your materials to our plant for galvanizing and then deliver them directly to a job site within a one day driving distance of our plant. If your facility or job site is beyond a one day drive, we are happy to handle or quote transportation of your materials using our network of carrier partners, saving you time and money

6. What are the primary ASTM specifications Galvan follows for galvanizing?

ASTM A123 – Standard Specification for Zinc HDG Coatings on Iron and Steel

ASTM A153 – Standard Specification for Zinc Coating HDG on Iron and Steel Hardware

ASTM A143 – Standard Practice Against Embrittlement of HDG Structural Steel Products

ASTM A384 – Standard Practice for Safeguarding Against Warpage and Distortion

ASTM A385 – Standard Practice for Providing High-Quality Zinc Coatings (HDG)

ASTM A767 – Standard Specification for Zinc Coated Steel Bars for Concrete Reinforcement

ASTM A780 – Standard Practice for Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings

ASTM A6386/D7803 – Paint / Powder Coat after Galvanizing Specifications

7. What masking materials do you recommend?

Masking is treating a portion of the steel surface so a specific area remains ungalvanized.

We recommend:

• GE 100% Silicone Caulk

• NAPA RTV Red

• DAP Household Adhesive

• Maskote Zinc Stop-Off

• Stop Galv

• Galva Stop

8. What marking pen do you recommend?

Markal Model # 96821G valve action paint marker. This will not affect the galvanizing process.

9. Is there a way to predict the life of a galvanized coating in my application?

Yes. The Zinc Coating Life Predictor is a free and easy- to-use software program available on the internet. The purpose of the software is to estimate a time to first maintenance for hot-dip galvanized steel subjected to various atmospheric environments. You can access the Zinc Coating Life Predictor at https://galvinfo.com: 8080/zclp/index.html.

10. Why does it look too thick, too thin, not shiny, different colors?

The appearance of the hot-dip galvanized coating can vary from piece to piece, and even section to section of the same piece. The most common reason for these variances is the chemistry of the steel itself, particularly the levels of silicon and phosphorous. This is beyond the control of the galvanizer. It is important to note, however, that appearance has no bearing on corrosion protection and in time, after exposure to the environment, all galvanized coatings will take on a uniform matte gray appearance.